Special shapes to make your robot design and build simpler, easier, quicker and lighter

Special shapes to make your robot design and build simpler, easier, quicker and lighter

Extrusions are made of 6061 T6 aluminum. The frame shapes have a 3/8 inch square top and bottom edge and corners with a thin plate between them. Sort of an I-Beam you can bolt to. The 3/8 inch square is beefy enough to drill and tap up to a size 1/4 inch or 6 mm thread into the sides, top, bottom or end. Tapping the end is particularly useful for constructing frames without use of welding or corner brackets. Of course 6061 is a weldable alloy, if you want or need to weld to it. The downsides of welding include significant loss of strength near the weld and distortion of the parts from welding shrinkage. If you are countersinking socket head cap screws into the squares, the head of a 1/4 x 20 screw is too large and weakens the frame structure. So 10 x 32 or 5mm should be the largest socket head cap screws used if countersinking the heads.

The slide shape fits over the 3/8 inch square. If it is to be used as a slide, a small amount of lubricant should be used to keep the aluminum to aluminum contact surfaces from binding.

The frame and angle shapes will allow direct and robust mounting of many of the gearboxes from AndyMark, Banebots and Vex. For example, the 3 inch frame fits the Nano gearbox well. Mounted against the hollow side, it clears the bearings and screws and bolts up flush.

The frames may be lightened by drilling the web. I recommend not cutting into the squares and leaving at least 5/8 inch material between the holes for shear strength. A metal cutting hole saw works well but should be used in a drill press or mill and the shape should be clamped down to the table. I recommend the Blair hole saws. Use a slow rpm. Or you can clamp the part in a bench vise and use a hand drill, again at the slowest Rpm with a light feed. Always use plenty of cutting lubricant.

We also sell drilling and tapping guides to facilitate assembly. Using the guides, you can construct a robot frame and mechanisms with a good woodworking miter chop saw with a carbide tipped blade and a hand drill. They are sized for 10-32 screws. If you use Socket Head Cap Screws, they are alloy steel and heat treated similar to grade 8 bolts. So they are tough and strong.

3 inch flat

Price per 8 Foot Piece: $24

Weight, lbs per foot: .607

2 inch flat

Price per 8 Foot Piece: $18

Weight, lbs per foot: .457

Slide

Price per 8 Foot Piece: $12

Weight, lbs per foot: .269

Slides over edges of extrusions

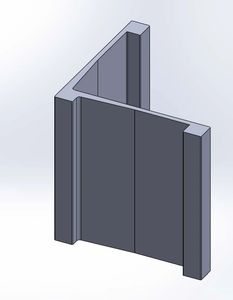

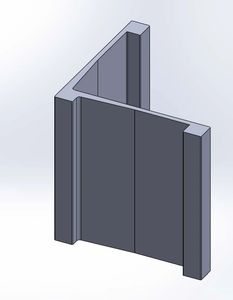

3 Inch Asymmetric Angle

Price per 8 Foot Piece: $41

Weight, lbs per foot: 1.10

2 x 2.25 Inch Asymmetric Angle

Price per 8 Foot Piece: $29

Weight, lbs per foot: .79

1 x 2 Inch Hollow Rectangle

Price per 8 Foot Piece: $35

Weight, Lbs per Foot: .967

3 x 3 Inch Asymmetrical Hollow

Price per 8 Foot Piece: $63

Weight, Lbs per Foot: 1.48

Set contains the angle plate, an end drilling and tapping tool, a tap driver, 2) #10 clearance drills, 3) #21 tap drills, 2) 10 x 32 spiral point taps, a box of 10-32 x 7/8 inch socket head cap screws, and necessary drill bushings and retaining screws. The drill bits are center cutting. When clamped to the extrusions, these tools allow you to drill and tap in the precise location and square for 10-32 fasteners to assemble frames. You must use plenty of cutting fluid when drilling or tapping. To tap, I chuck the tap in a variable speed hand drill and power tap at a slow speed. Reverse the drill to back the tap out. Do not use a standard straight flute hand tap. The chips will bind the tap and break it. You can use a spiral point tap if you have a through hole, or drill the tap hole at least .375 inch deeper than you need to thread. Or you can use a spiral flute tap for a blind hole. When drilling a deep hole, drill about 1/8 inch, pull the drill out, clean the chips and apply cutting oil, then drill another 1/8 inch until you are at the depth you want. In addition to holes for all the Robot extrusions, there are 5 holes to fit the end of the 1 inch extrusion from Rev Robotics. There are also 3 holes which will fit some extrusions I have not pushed yet (the hollow triangle shapes).

Robot Extrusions

Chehalis Bicycle Inc 675 NW Saint Helens Ave Chehalis, WA 98532 us

Copyright © 2023 Robot Extrusions - All Rights Reserved.

Powered by GoDaddy Website Builder